Cement Company © 2015. Privacy Policy

All business lines clearly improved their sales volumes year on year. Thanks to this growth in sales volumes and successful price increases in major markets, revenue improved moderately to €13,547 million (previous year: 12,128) despite substantial negative exchange rate effects of €417 million.

Our company remained consistent and disciplined in pursuing the targeted expansion of its market position in the cement business line in growth countries. Cement and clinker facilities with a capacity of over 5 million tonnes were put into operation.

PLANT STATISTICS

OUR COMPANY IS GROWING RAPIDLY AND STEADILY IMPROVES INDICES FROM YEAR TO YEAR

The design capacity of the plant - 2 thousand tons of dry mixes per month, reaching these indicators is scheduled for the end of 2015.

Speaking about changes in our policy, we’ve realised how sustainable development is important to us. Since the advent of the product - cement and concrete, in cement and concrete production we use natural resources. We understand that natural resources are exhaustive and should be used sparingly. Therefore, we have defined sustainable development as a strategic goal.

HOW CEMENT IS MADE AT CEMENT COMPANY

CEMENT FROM

CLINKER

ENVIRONMENTAL

CONTROLS

The cement produced by heating clay and lime to ultra high temperature - 1450 ° C and above. As a result of the melting clinker granules are formed - the basis of any of the cement mixture.

For obtaining of cement clinker is mixed with a few percent of gypsum and finely milled. Gypsum controls the speed of setting, it may be partially replaced by other forms of calcium sulfate. Some specifications are allowed to add other materials during grinding.

Reducing the negative impact on the environment - a priority of environmental policy. The company has developed and implemented environmental programs for the improvement of ecological situation and reduction of emissions into the environment.

MANUFACTURING PROCESS

Production of clinker - the most complex and energy-intensive process. It requires a lot of capital and operational costs. This determines the maximum savings requirement of clinker, replacing it whenever possible by hydraulic additives and impurities.

1.

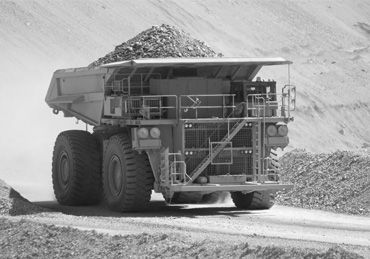

THE EXTRACTION OF RAW MATERIALS IN QUARRIES.

Blasted rock which size of pieces is up to 1000 mm in diameter are stowed by excavator on vehicles and sent to the factory.

2.

PREPARATION OF RAW MATERIALS FOR CALCINING

In the wet process, preparation and mixing of the raw materials is carried out in the presence of water, and in dry - materials are ground and mixed in dry form.

3.

FIRING THE RAW MATERIAL (CLINKER PRODUCTION)

Firing the raw material mixture - center stage of cement technology. For firing used two types of furnaces - mine and rotating.

4.

WAREHOUSING, PACKING AND SHIPPING OF CEMENT TO THE CONSUMER.

From silos cement is unloaded into special covered railroad cars, tanks or cement trucks. Part of it is packed in multilayer paper bags, 50 kg of cement in each.

WE LIVE IN A RAPIDLY CHANGING WORLD, AND WE WITNESS PROFOUND CHANGES IN SOCIETY, CONSCIOUSNESS, FOUNDATIONS, BUSINESS. BUT INVARIABLE WERE AND STILL ARE THE BASIC PRINCIPLES ON WHICH THE ACTIVITY OF THE COMPANY HAS BEEN BUILT - HONESTY IN RELATIONS WITH CUSTOMERS AND PARTNERS, AN EXTENSIVE RANGE OF PRODUCTS, CONSISTENTLY HIGH QUALITY OF OUR CEMENT, ACCESSIBLE PRICES, SOCIAL RESPONSIBILITY, THE DESIRE FOR STABILITY. I AM HAPPY TO WORK IN A TEAM OF SOUL-MATES, A TEAM THAT IS ABLE TO SOLVE PROBLEMS OF ANY COMPLEXITY.

DAYLE PETERS

COMPANY LEADERS

Independent non-executive director.

She is a professional legal member of the Cyprus Bar Association since 1992.

JESSICA PRISTON

Director General

Was appointed General Director of the company on March 28, 2014.

SAM KROMSTAIN

Financial Director

Has been appointed Finance Director in 2014.

ALAN SMITH

Technical Director

He has been appointed Technical Director in June 2014.

JOHN FRANKLIN